Coating and Filter Technology

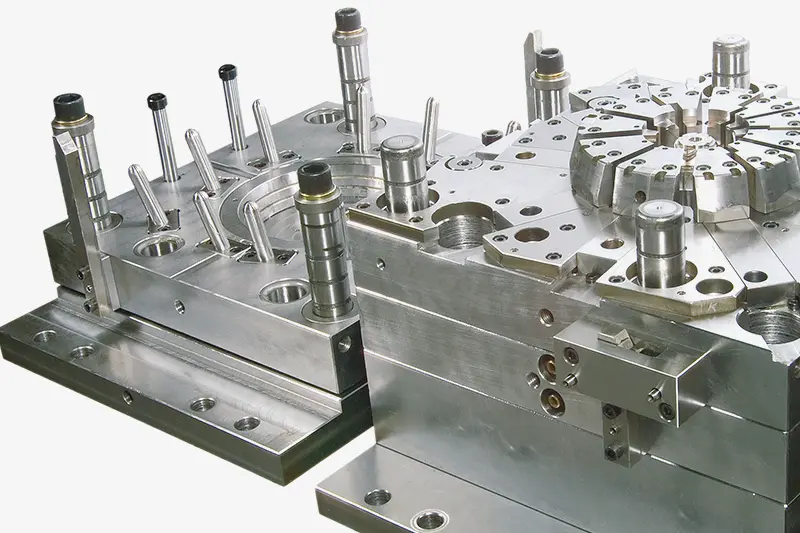

To fully derive a lens performance in accordance to various purposes, an optimal coating needs to be applied in addition to optical lens design technology.

By applying a coating on the lens surface various effects and functions can be achieved such as optical performance enhancement and surface protection.

TAMRON conducts lens and coating development for various applications, for instance, surface protection for photographic lens, durability enhancement for automotive camera, and surveillance camera.

Moreover, TAMRON is holding a uniform coating technology for wide curved surfaces on wide-angle or fish-eye lenses. Recently, to achieve a coating technology suitable new fields, Tamron is developing a filter/coating technology capable of precisely transmitting a specific wavelength for medical or fluorescence imaging with laser.

-

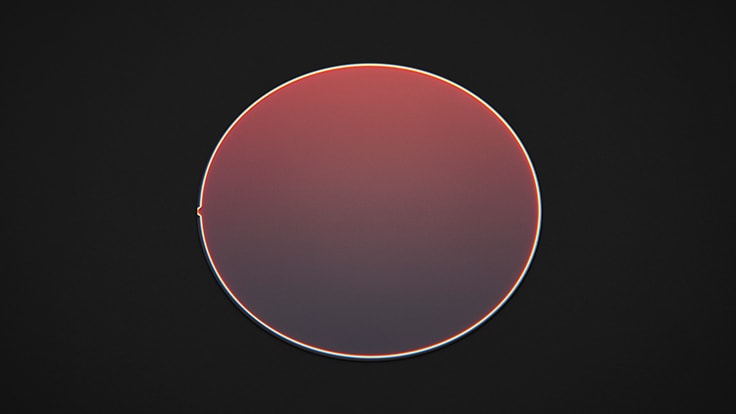

Thin film optical filter (Notch Filter)

High optical density (shielding performance)

-

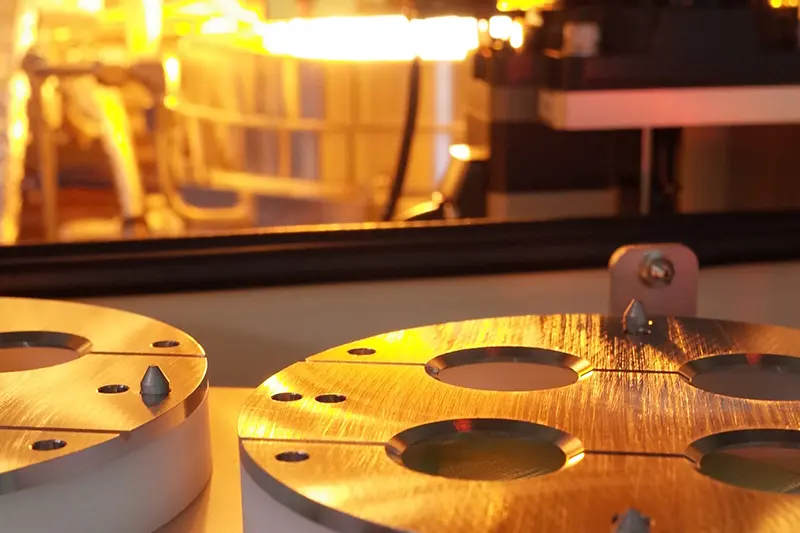

High Temperature Resistant Plastic Lens Coating

Optimized layer deposition conditions to suit broad temperature variations for automotive lenses

-

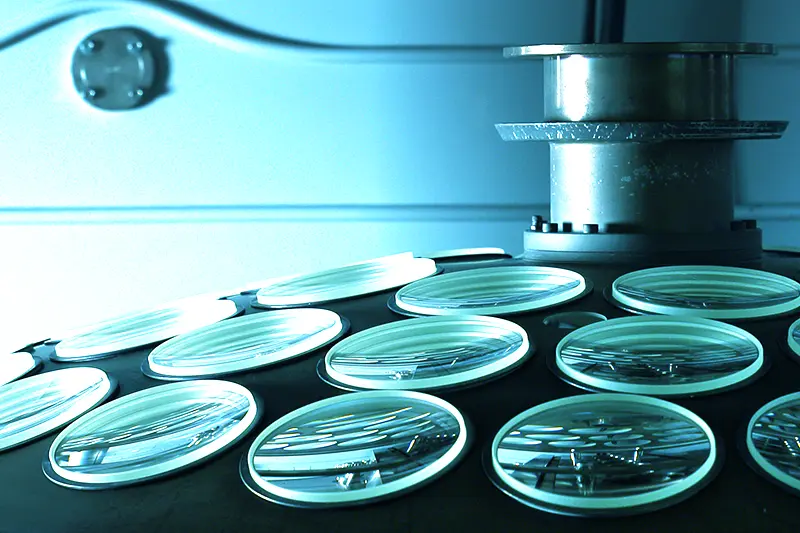

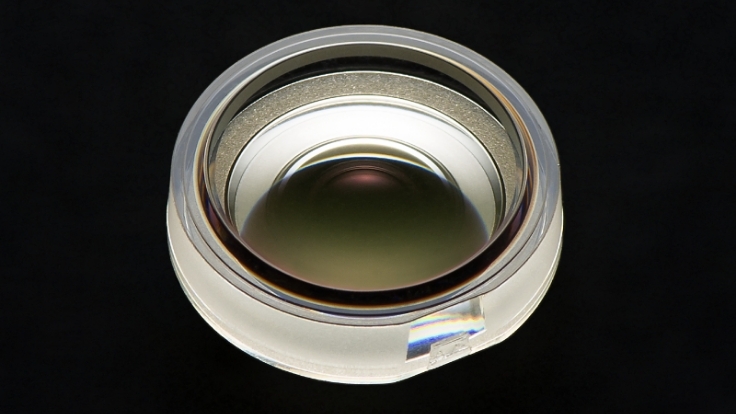

Anti-reflection coating for convex surfaces (AX Coating)

A coating technology that makes uniform vacuum deposition thickness at the peripheral areas and central areas

-

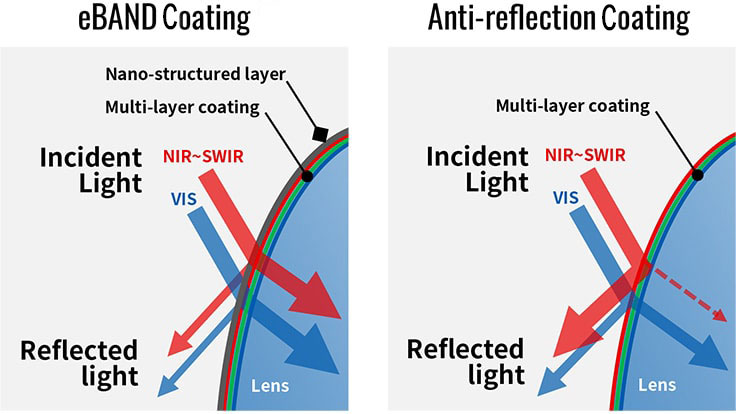

eBAND Coating

Wide band anti-reflection coating (from visible light to SWIR light range)

-

Fluorine Coating

Wiping durability enhancement

TAMRON LABS

-

Opto-Science R&D

Opto-Science R&DOptical Technology for High-Power Laser

Transmission & processing technology development for laser

-

Opto-Science R&D

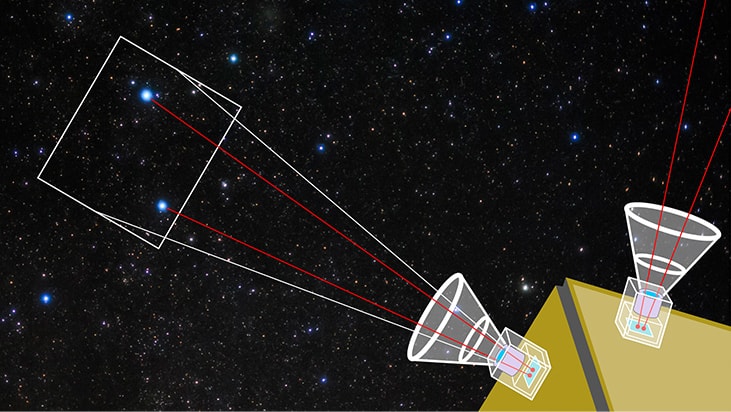

Opto-Science R&DDevelopment of optics for satellite implementation

Optics for free space optical communicationHigh-precision beam control technology

-

Opto-Science R&D

Opto-Science R&DDevelopment of optics for satellite implementation

Optical technology for star trackersDesign technology for straylight shield and radiation resistance