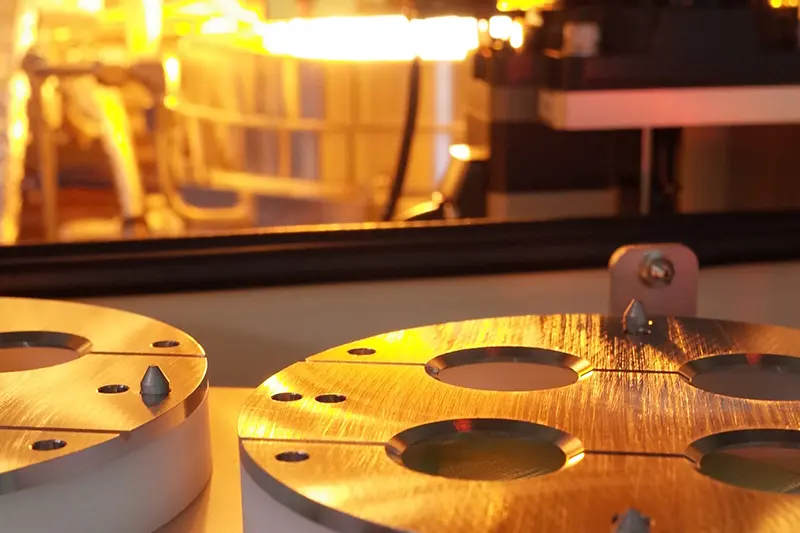

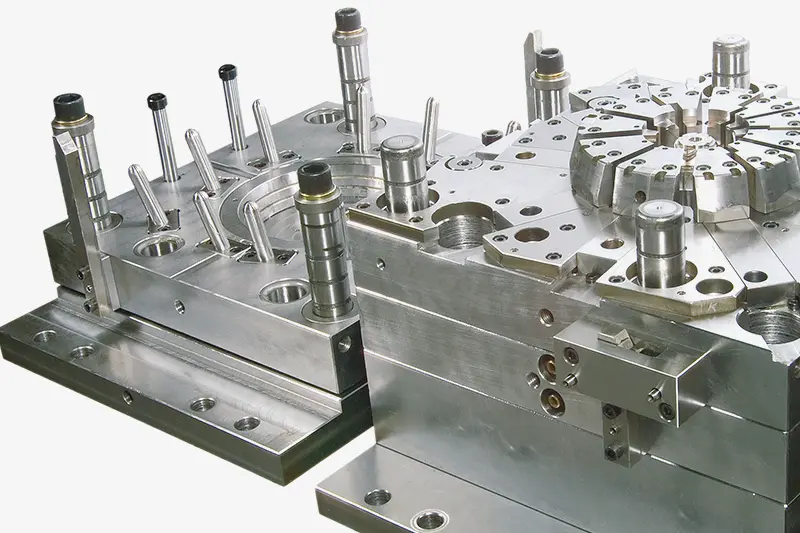

Resin Forming/Molding Technology

Plastic lenses are able to be formed into complex shape such as a complicated aspherical and flange shapes which are difficult to be formed with glass materials, this contributes to higher productivity and weight savings.

Plastic lenses are utilized for various applications such as imaging optical system, lighting optical system for projection and diffusion with a free curved surface used for projector and automotive and low-profile Fresnel lens.

Recently, advancing plastic materials, plastic lens is utilized for lens corresponding to a long wavelength band such as NIR(Near Infrared) for sensing and communication usage, cylindrical lens and lens array for laser usage. In addition, plastic lens is formed as optical element with aspherical lens using material cured by ultraviolet rays and heat. Some of the challenges of plastic material such as thermal expansion and density variation due to heating and discoloration due to aging have been solved by evolution of material. TAMRON produces value-added products to the world by creating a plastic lens endurable in adverse environment which used to be difficult to be manufactured.

Furthermore, as a fusion of forming technology, integrating far infrared glass material with plastic material and improving compatibly optical lens with transmittance and fucus, TAMRON conduct proactively technology development in a new realm.

TAMRON LABS

-

Opto-Science R&D

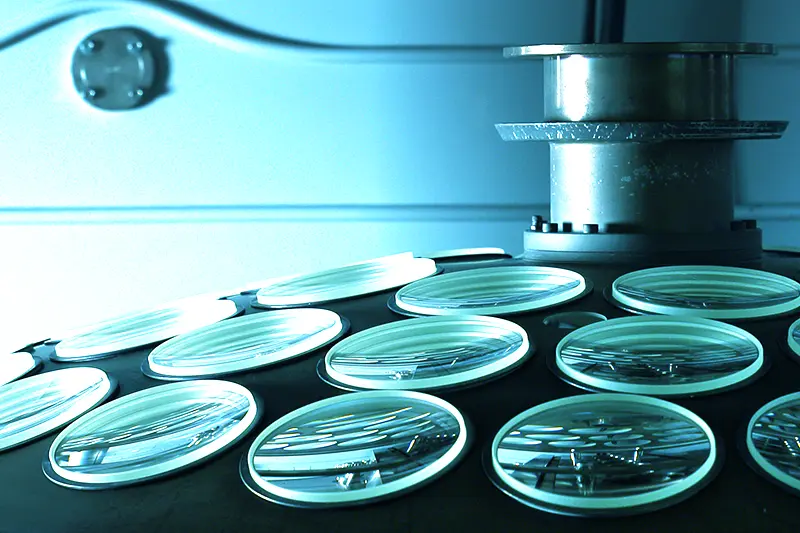

Opto-Science R&DOptical Technology for High-Power Laser

Transmission & processing technology development for laser

-

Opto-Science R&D

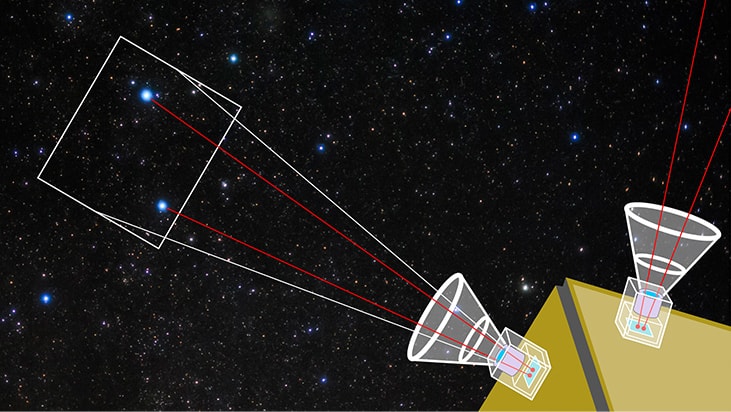

Opto-Science R&DDevelopment of optics for satellite implementation

Optics for free space optical communicationHigh-precision beam control technology

-

Opto-Science R&D

Opto-Science R&DDevelopment of optics for satellite implementation

Optical technology for star trackersDesign technology for straylight shield and radiation resistance