Lens Processing Technology

In the lens processing, in order to manufacture a lens with the required performance, various conditions need to be adjusted by selecting the machine used for manufacturing and adjusting the polishing time according to the magnitude of curvature and the characteristics of the material.

For example, high-pixilation and high-definition are yearly advanced in CMOS image sensor used in cameras and a lens surface-roughness, unevenness or waviness negatively effects the lens imaging performance.

To enable a highly accurate lens, TAMRON reflect a simulation result to a processing accuracy from the optical designing stage.

TAMRON’s lens processing technology is covering a wide range, multiple lens bonding with curved surfaces, processing with plane lens and prism lens, and prism lens bonding with each other. From now on, as a new usage, optical lens is expected to be used with laser and to be required a complicated irregular shape or prism shape integrating various technologies.

To produce multifarious lenses required in the future, TAMRON is newly developing and improving the processing technology and handing down its established expertise by cooperating the lens processing know-how and the optical development technology.

-

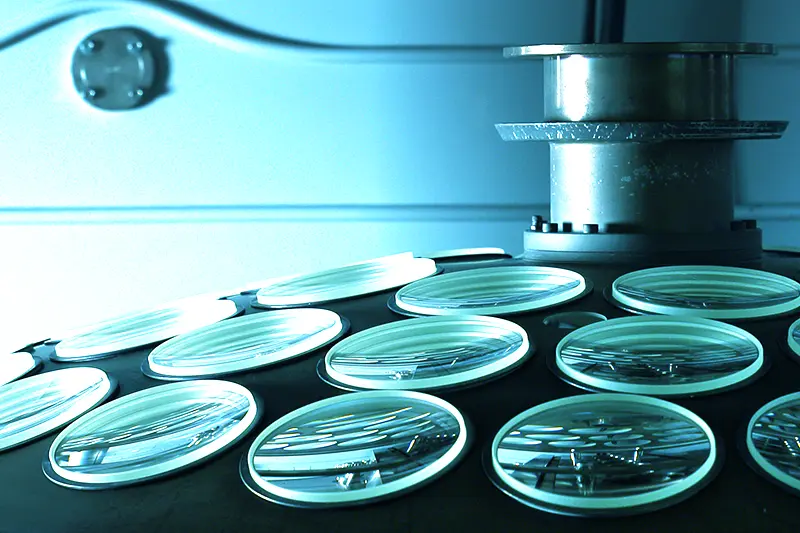

Small-diameter lens

Small-diameter lens achieved with advanced processing technology

-

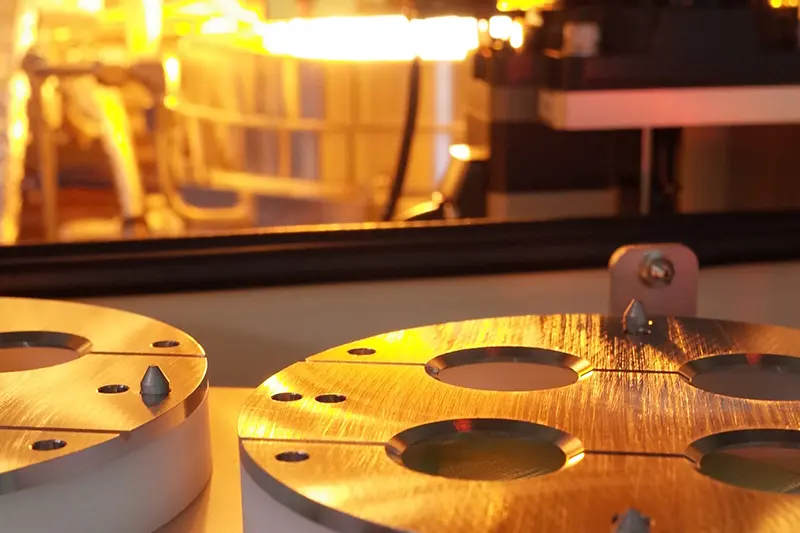

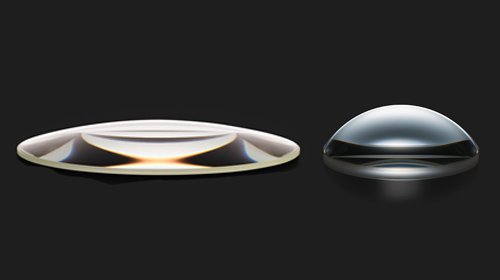

Large-diameter lens

Processing technology with superior surface accuracy applicable to high resolution and high precision

-

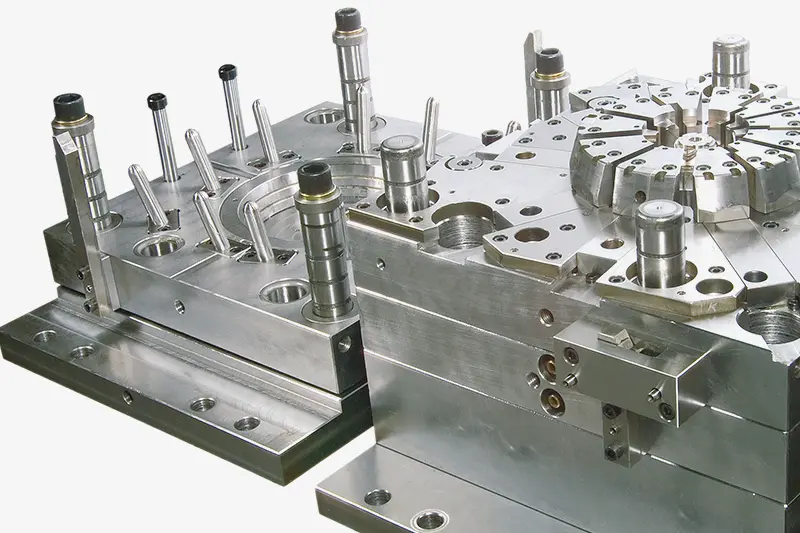

Glass molded optical lens with special form

inflection point (seagull wing shaped lens processing)

-

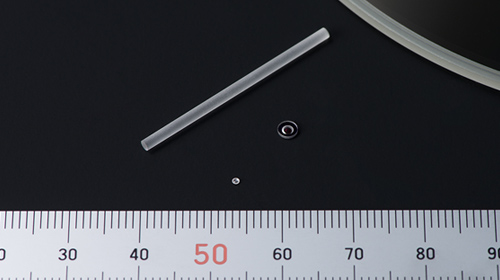

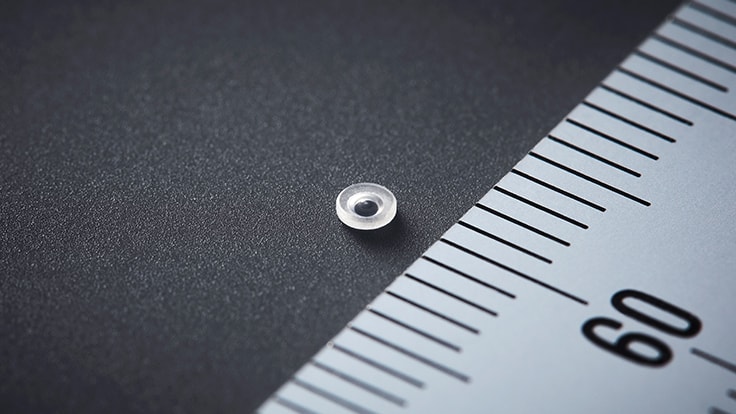

Ultrathin and small-diameter glass molded lens

Pursue Thinness and Smallness

TAMRON LABS

-

Opto-Science R&D

Opto-Science R&DOptical Technology for High-Power Laser

Transmission & processing technology development for laser

-

Opto-Science R&D

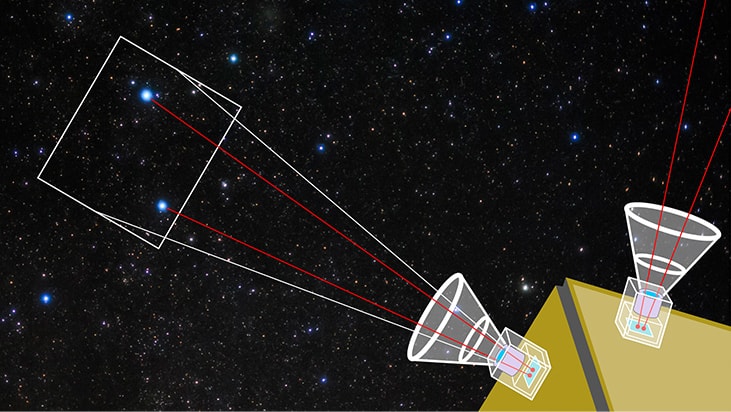

Opto-Science R&DDevelopment of optics for satellite implementation

Optics for free space optical communicationHigh-precision beam control technology

-

Opto-Science R&D

Opto-Science R&DDevelopment of optics for satellite implementation

Optical technology for star trackersDesign technology for straylight shield and radiation resistance